From Bean to Bar: The Fascinating Journey of Molded Chocolate

Chocolate is a beloved treat enjoyed by millions around the world. But have you ever wondered about the intricate process that transforms raw cacao beans into the delicious molded chocolate bars we savor? From bean to bar, the journey of chocolate involves a blend of tradition, art, and science. Let’s delve into this fascinating journey and uncover the steps that bring chocolate from tropical cacao farms to your local store shelf.

The Origins: Cacao Beans

1. Cultivation and Harvesting

The journey begins in tropical regions near the equator, where the cacao tree (Theobroma cacao) thrives. Cacao farmers cultivate these trees, which produce pods containing the precious cacao beans. Each pod, about the size of a small football, holds 20 to 50 beans encased in a sweet, tangy pulp.

Harvesting is a labor-intensive process. Skilled farmers use machetes to cut the pods from the trees, ensuring they don’t damage the delicate flowers and branches. Once harvested, the pods are split open to reveal the cacao beans, which are scooped out and prepared for fermentation.

2. Fermentation

Fermentation is crucial for developing the beans’ complex flavors. The beans, along with the pulp, are placed in shallow containers or baskets and covered with banana leaves. Over several days, naturally occurring microbes ferment the beans. This process generates heat and initiates chemical changes that reduce bitterness and develop characteristic chocolate flavors.

3. Drying

After fermentation, the beans are spread out to dry under the sun. This stage can take up to a week. The beans are regularly turned to ensure even drying and to prevent mold growth. Proper drying is essential to reduce moisture content and prepare the beans for storage and shipping.

Transformation: From Bean to Chocolate

4. Roasting

Once the dried beans reach the chocolate manufacturer, they undergo roasting. Roasting enhances the beans’ flavor profile by bringing out the deep, rich chocolate notes. The temperature and duration of roasting vary depending on the desired flavor, but typically, it ranges between 250°F to 350°F and lasts from 30 minutes to two hours.

5. Cracking and Winnowing

After roasting, the beans are cracked to break the shells and release the nibs—small pieces of pure cacao. The mixture is then winnowed to separate the nibs from the shells. The nibs are the core ingredient for chocolate production, while the shells are often used as mulch or animal feed.

6. Grinding and Conching

The nibs are ground into a thick, gritty paste known as cocoa mass or cocoa liquor. This paste contains both cocoa solids and cocoa butter. During the conching process, the cocoa mass is continuously mixed and aerated to refine the texture and flavor. Conching can last from several hours to several days, depending on the desired smoothness and flavor profile. This step is crucial for eliminating bitterness and developing the chocolate’s final taste.

7. Tempering

Tempering is the process of carefully heating and cooling the chocolate to stabilize the cocoa butter crystals. Proper tempering ensures that the chocolate has a glossy finish, a satisfying snap, and a smooth mouthfeel. This step is essential for producing high-quality molded chocolate bars.

The Final Touch: Molding and Packaging

8. Molding

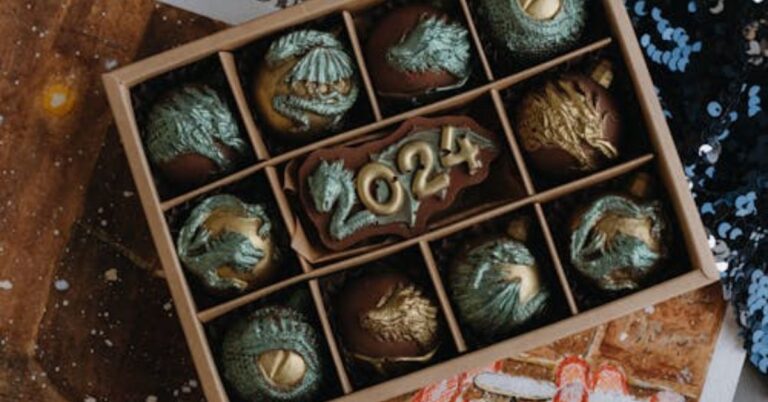

Once tempered, the chocolate is poured into molds to create bars, shapes, or other confections. The molds are gently vibrated to remove air bubbles and ensure an even distribution of chocolate. After molding, the chocolate is cooled, usually in a controlled environment, to allow it to set properly.

9. Packaging

The final step is packaging the chocolate bars. Packaging not only protects the chocolate from damage and contamination but also preserves its freshness and flavor. Many chocolatiers use eco-friendly and aesthetically pleasing packaging to appeal to consumers.

Conclusion

The journey from bean to bar is a remarkable process that combines agriculture, science, and artistry. Each step, from the careful cultivation of cacao trees to the meticulous tempering and molding of chocolate, plays a vital role in creating the delicious bars we love. Next time you indulge in a piece of chocolate, take a moment to appreciate the craftsmanship and dedication that goes into every bite. This intricate process not only results in a delightful treat but also supports the livelihoods of countless farmers and artisans around the world.